Bringing Order, Visibility, and Speed to The Factory Floor

A single system that connects production, inventory, and quality, giving teams the clarity they need to prevent shortages, delays, and costly mistakes.

The Challenge

Food production manufacturers often rely on spreadsheets, paper batch sheets, and disconnected tools or outdated ERPs to run daily operations. This creates blind spots, delays, and costly mistakes on the production floor. Teams struggle to stay aligned, and customers feel the impact.

- Supervisors juggle handwritten batch sheets and Excel logs, making it difficult to know which batches are running, delayed, or ready for packaging in real time

- Stock counts live in outdated spreadsheets or handwritten notes, leading to unexpected shortages, over-ordering, and last-minute scrambles to keep production moving.

- When a quality issue appears, staff must dig through binders and multiple files to understand which ingredients were used, slowing down investigations and risking compliance problems.

- Without structured reminders or system-generated alerts, teams miss reorders, overlook QA deviations, and fall behind on must-ship orders as priorities get lost in daily chaos.

- Important documents are spread across folders, PDFs, and shared drives, forcing supervisors to waste time gathering information instead of managing production.

The Solution

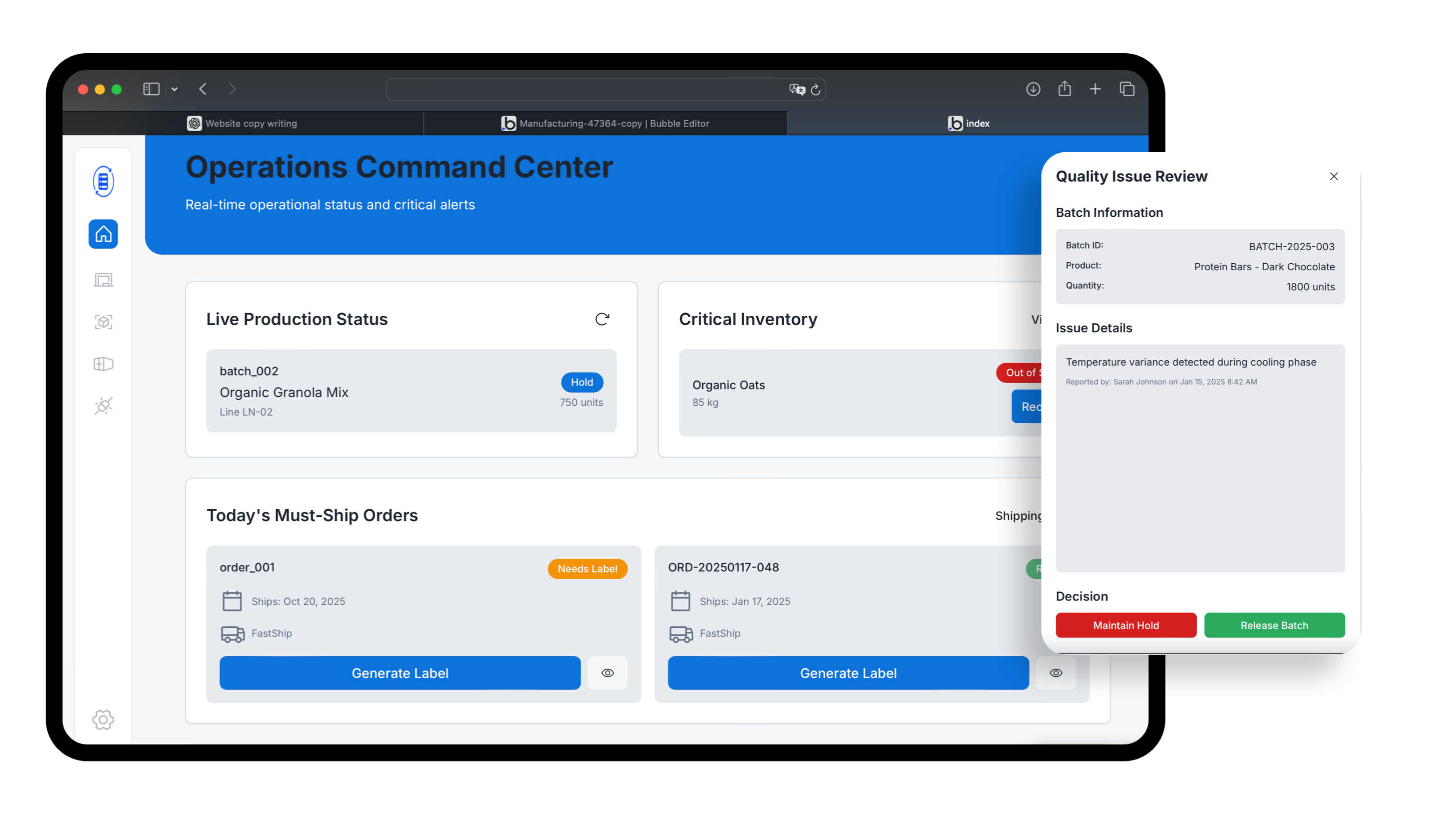

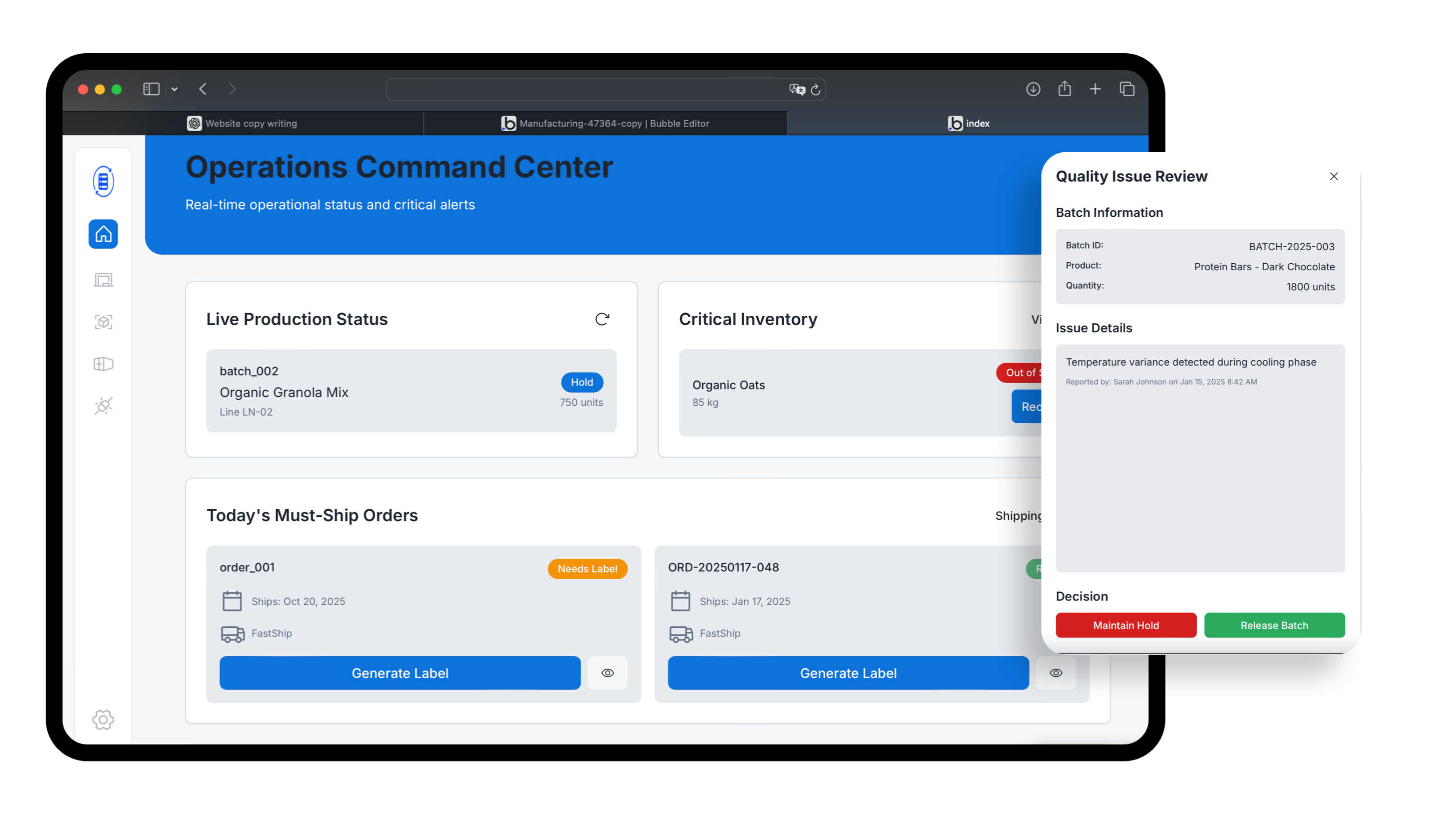

The dashboard centralizes all mission-critical production insights, giving teams instant visibility into what’s happening on the floor. Instead of checking scattered spreadsheets or asking around, operators and managers get real-time clarity the moment they log in.

Live production status for active batches

No more walking around to confirm progress. You can instantly see which batches are running, delayed, or completed, so bottlenecks surface before they become problems.

Today’s must-ship orders always front and center

Shipments that need attention today appear immediately, helping your logistics team prioritize work and avoid last-minute scrambles.

Critical inventory alerts for raw materials and packaging

Low or out-of-stock items trigger real-time alerts so production doesn’t stall due to missing ingredients or materials.

Quality assurance alerts for flagged production events

QC issues show up the moment they occur, allowing quick corrective actions and traceability across teams.

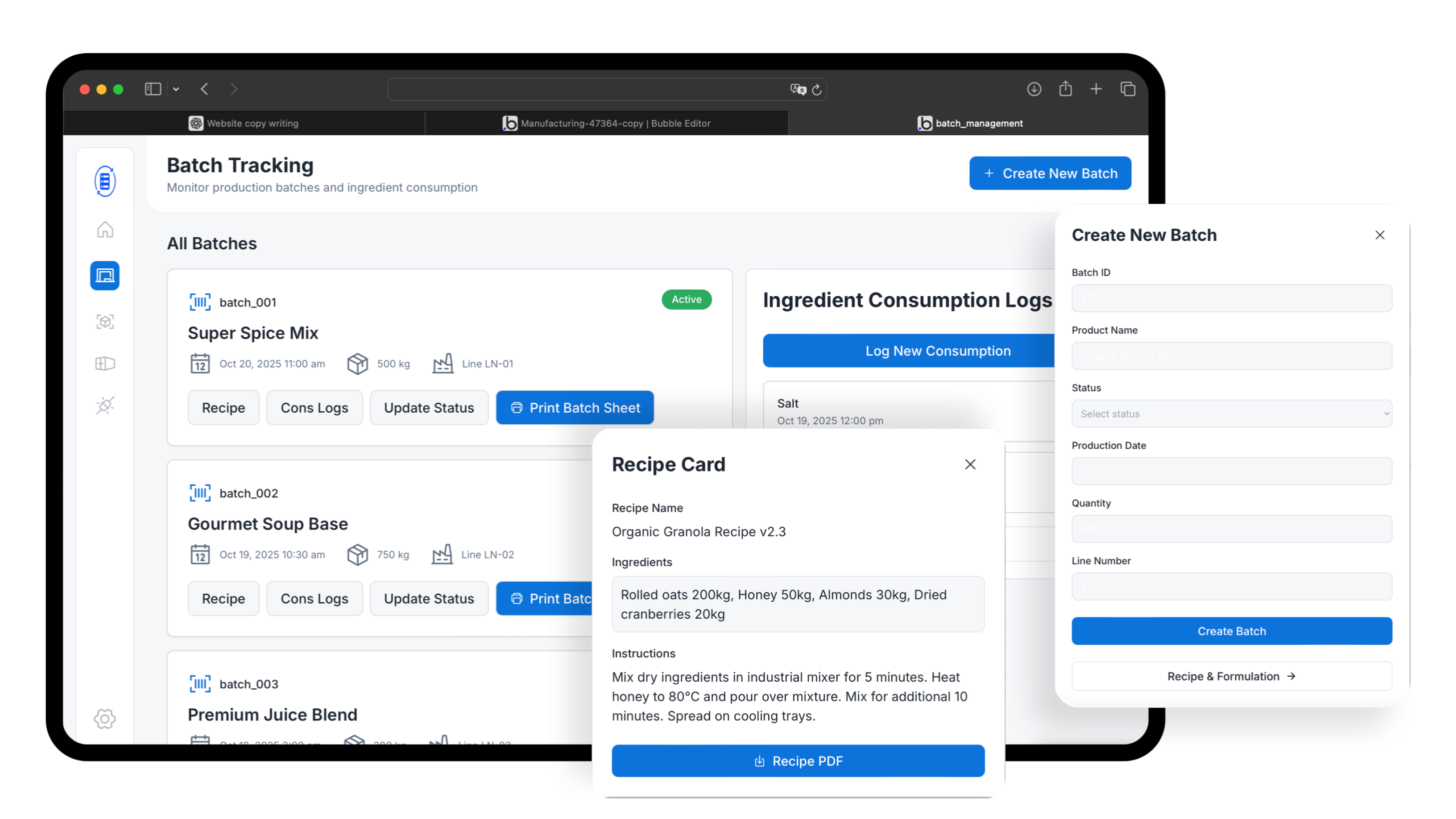

The batch tracker organizes production from start to finish, ensuring every batch is documented, traceable, and easy to manage. Teams can create, monitor, and update batches without digging through paperwork or outdated systems.

Clear batch lists with real-time statuses

You always know what’s running, what’s pending, and what needs review — no more chasing supervisors for updates.

One-click access to recipes and formulations

See exactly what materials were consumed and how much was allocated, helping maintain accuracy and compliance.

Quick status updates with built-in actions

Whether a batch moves to mixing, cooking, cooling, or packaging, status changes happen in seconds and sync across the system.

Create new batches through a guided pop-up

Operators can launch new batches through a clean, structured form that reduces manual mistakes and speeds up setup.

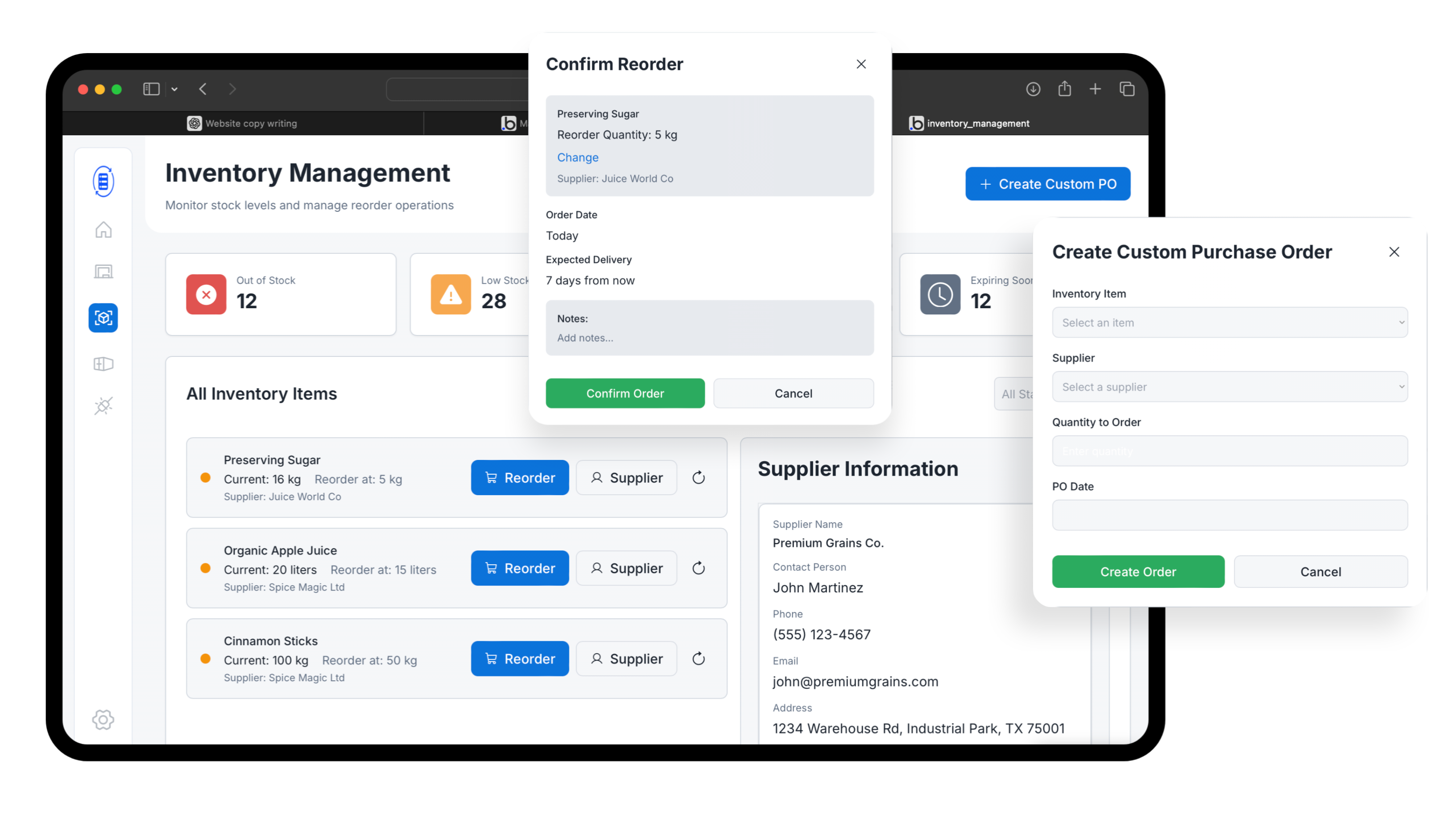

Inventory becomes predictable and organized instead of chaotic. The module gives purchasing, production, and suppliers the transparency needed to keep operations running without shortages or guesswork.

Key KPI cards for in-stock, low stock, and out-of-stock counts

At a glance, you know exactly where inventory stands and what needs attention before it becomes a production issue.

Detailed item lists with reorder actions

Every ingredient and material includes buttons to reorder instantly — no switching tools or drafting emails manually.

Supplier information and contact access in one click

Teams can open a supplier’s details and reach them immediately, speeding up procurement and reducing downtime.

Create new purchase orders effortlessly

A structured PO creation form ensures accurate orders and faster procurement cycles.

Save Hours Every Week

Less time spent updating spreadsheets and chasing missing details translates into more client-facing hours.

Close Deals Faster

Centralized, accurate data helps agents move prospects through negotiations and approvals with fewer delays.

Cut Costs Every Month

Reduce reliance on multiple tools and minimize the need for extra administrative support.

Our Process, Simplified

1. Workflow Analysis

We study your business processes carefully to identify pain points and opportunities.

2. Custom App Design

We create a wireframe for a tailored solution with a clear interface and workflow.

3. App Development

The actual developement of the app requires building a database, and working on the front-end and back-end, to create fully integrated platform with all features you need.

4. Delivery & Testing

We deliver the app, train your team, and test everything to ensure smooth operations.

5. Ongoing Support & Maintenance

We stay with you to ensure smooth operations and future improvements. With one click inside your app.

Contact Us

If you have any questions please reach out.

Contact@webriv.com